Project Scope

K is a leading developer of semiconductor and display related equipment and is a domestic mid-sized enterprise that produces core equipment for semiconductor production lines, such as CMP (Chemical Mechanical Polishing), Wet Station, Gas Cabinet and Ceria Slurry. Controllers applied to the semiconductor process must meet the high reliability and performance standards required by complex advanced systems, characterized by minimum downtime from sudden failure and prompt recovery after malfunction.

Client’s Challenge

Among the company’s semiconductor equipment range, the Gas Cabinet is a core facility with various PLC devices that operate 24/7. Company K plans to develop a backup PLC for uninterrupted systems as PLC devices require backup controllers in case of problems with the device. This project requires the development of an extremely compact system with all necessary functions, since an auxiliary PLC must be installed in a very limited space, outside of the space of PLC devices installed in the existing gas cabinet.

Solution & Implementation

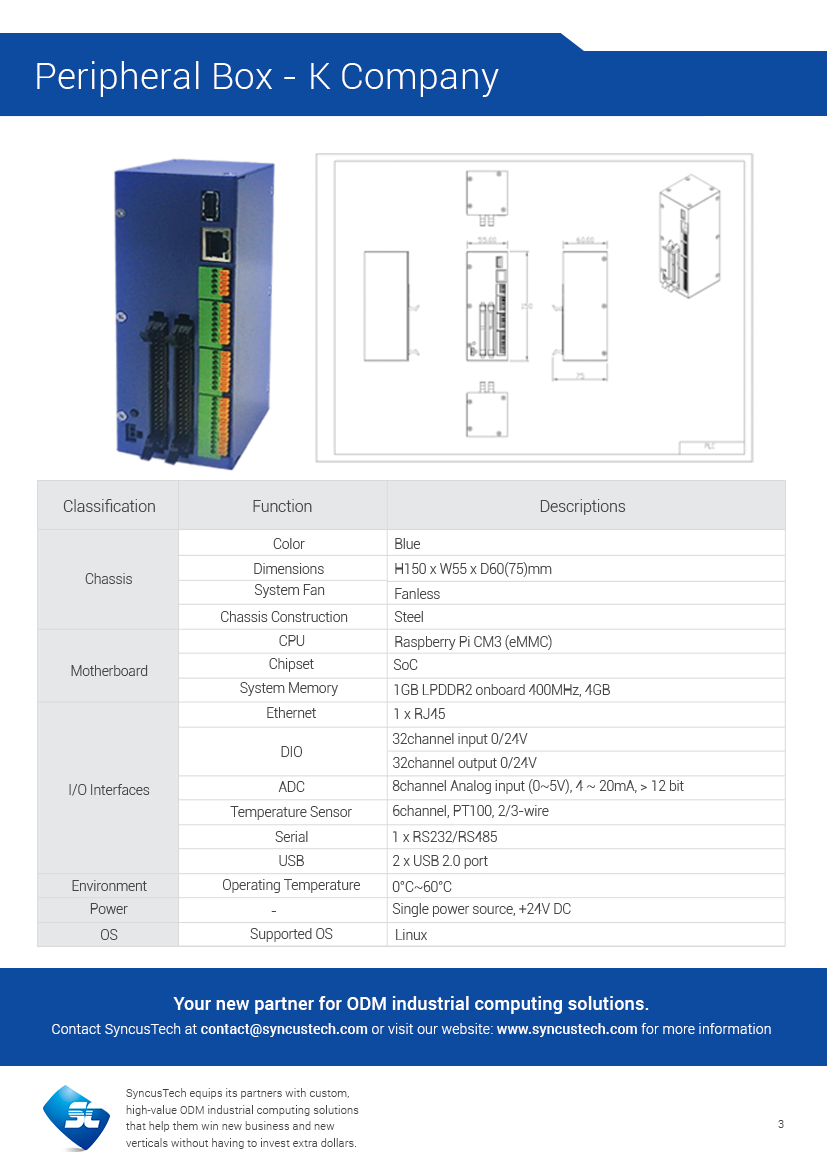

SyncusTech has developed a fanless type high-reliability uninterrupted module with Raspberry Pi for low-power low-temperature systems in order to meet the requirements of installation in cabinets with extremely limited space. The chassis is designed in 55 x 77 x 150 mm and can be mounted on existing cabinets by Din Rail. A variety of interface functions have been actualized, such as DIO (Digital Input/Output), designed for DI 32 channel and DO 32 channel, 8 channels for ADC (Analog to Digital Converter) and 6 channel for temperature sensor. I/O port of each interface is configured through four types of PCB design inside. The advantage of this structure is that it can be flexibly applied by adding PCB modules when new functions are expanded. RS232/RS485 and Ethernet are configured to support various industrial communication methods.

Conclusion & Benefits

SyncusTech has developed modular PCBs to flexibly accommodate needs in the field. We consider not only the needs of one project, but also cases requiring more channels for DIO, ADC, and temperature sensor. Additional consideration was also given to applying the CAN communication method. We have developed a gas cabinet, which is already installed on production lines so that we can respond more flexibly in the field.