Project Scope

A systems integrator specialized in the field of production line manufacturing won a project from an automobile manufacturer. The goal of project was to convert the existing control system which was made of simple dumb terminals, into a complex, high-performing control system including enlarged I/O ports for a PLC interface and control of a lighting system through DIO. Therefore, the system integrator had to consider an efficient way of integrating these various functions.

Client’s Challenge

Considering the environment of the automobile factory, the controller required a fan-less panel PC which is a low heat, low power and high performance. In addition, locking rear port cables needed to be designed to secure loosening from vibration in the factory. Two PCI slots for the PLC interface were necessary. DIO for relay control and an alarm buzzer were also needed. All functions need to be accommodated on the small motherboard with EPIC form-factor (115*165). A display system was needed to upgrade the existing warning light to an LED system.

Solution & Implementation

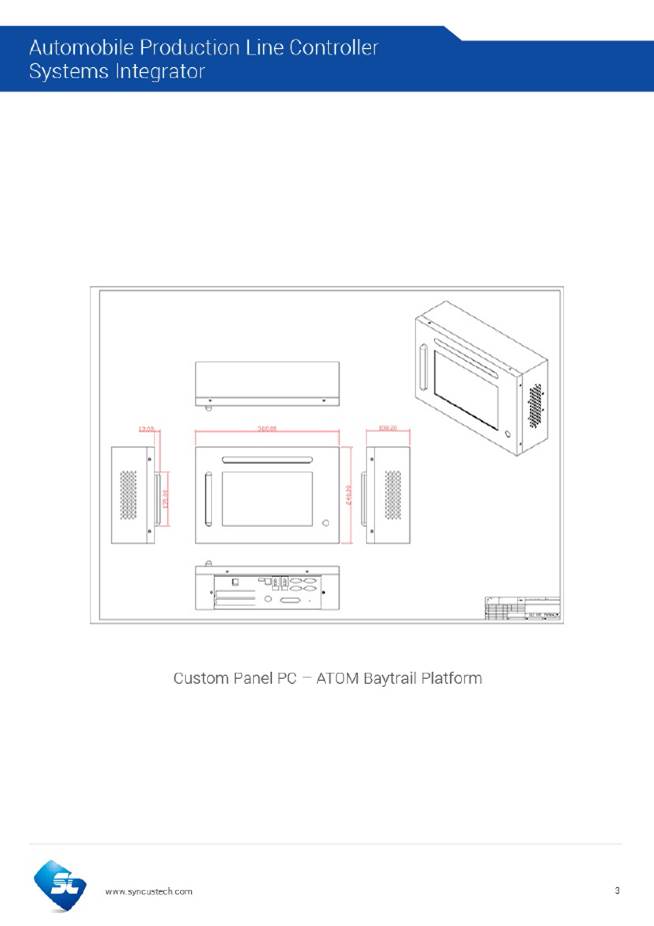

Most of all, SyncusTech selected the latest ATOM Baytrail platform from Intel to implement and designed 10.2” low heat, low power, high performance, fan-less panel PC. However, the Baytrail platform does not support PCI and relay control via DIO. Therefore, SyncusTech’s R&D team developed a converter card from mini PCIe to PCI, and a module to expand internal DIO and control relays. Thus SyncusTech was able to fulfill all of the customer’s requests. Furthermore, the concise panel PC accommodated the original warning light function by controlling a RGB LED bar through a DIO relay sub-board.

Conclusion and Benefits

The systems integrator reduced production costs drastically by integrating various production facilities like the control terminal of machine tools, the PLC controller, and a warning light into one compact panel PC. As a result, the automobile manufacturer was very satisfied with the simplification of their production line and the efficient control of the whole system. The systems integrator is looking forward to winning the second production line project from the automobile manufacturer.