SyncusTech was awarded a $300,000 grant for 2018 after being selected a part of the New Product Development Project, sponsored by the Korean Ministry of SMEs and Startups. The project’s goal is to propose technological development organized by demand type (midsize vs large companies, public and government institutes, etc.) In this way, the government is supporting and promoting the growth of small and medium enterprises that possess technological competitiveness. Small and medium enterprises that develop successfully will gain the opportunity to establish a beneficial relationship with other enterprises in the project. Also, the source of demand will ensure purchases for a certain period of time so that development results will not decline. With factory automation specialist Aim Systems Inc. as a partner, we have organized a technology consortium with KCL (Korea Conformity Laboratories) as a joint development institute in order to ensure product reliability. SyncusTech, as the hosting organization, will lead the project. The project will serve to expand our spectrum of products related to smart factory solutions, allowing us to better help actualize many companies’ innovative vision of smart manufacturing factories.

As the combination of manufacturing with Information and Communication Technology (ICT) becomes the core of the 4th industrial revolution, we are developing various Factory hardware Solutions that will seamlessly integrate with MES smart factory software. Some of those offerings include customized distributed servers, smart controllers, and peripheral boxes. System Integrator companies develop their own software solutions for clients, but ready-made hardware offers limited functionality and holds the system back from being what the SI would intend. Therefore, it is beneficial from a hardware perspective to have products customized for the MES software and tailored to the manufacturing site. With this in mind, SyncusTech has developed integrated solutions allowing optimized software to be embedded within the customized hardware.

SERVER

SERVER

SERVER

A. Custom distributed server

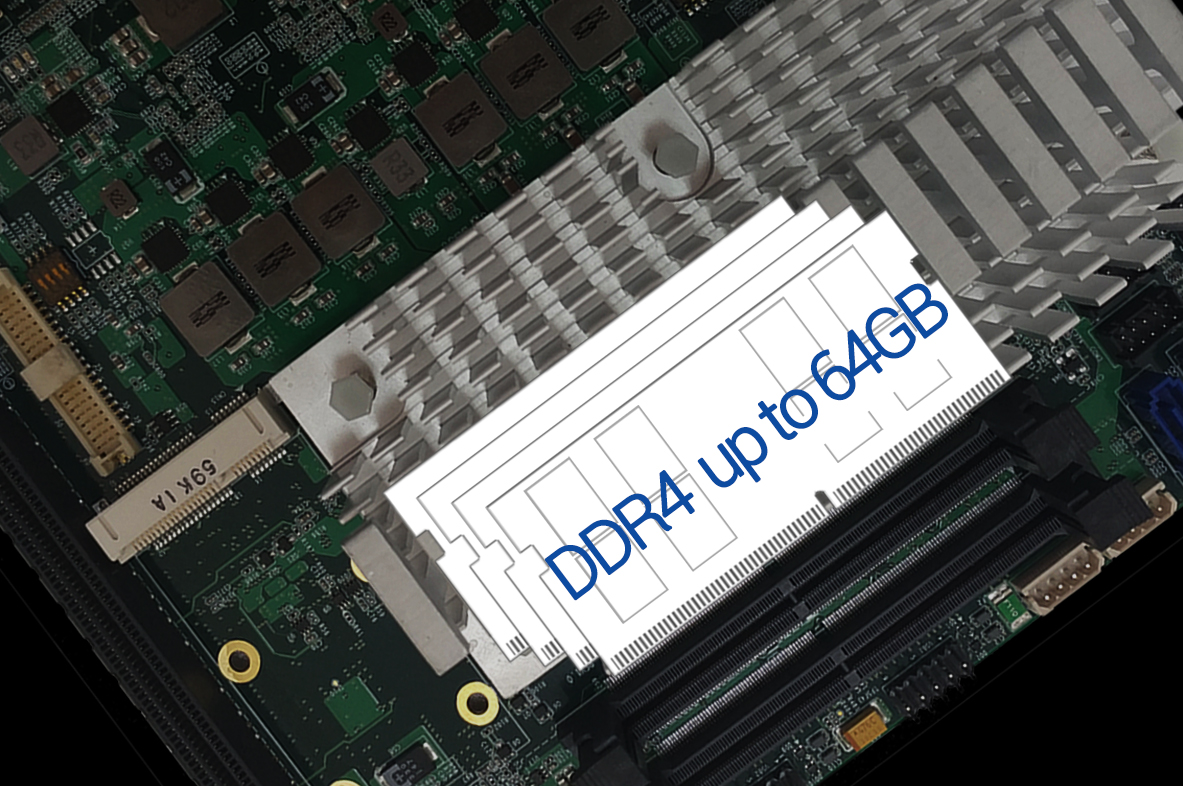

One of our MES offerings is a customizable, distributed server. A distributed server is a cloud computing system that implements IaaS (Infrastructure as a Service) for factory automation. The system utilizes multiple nodes (distributed computers) to perform complex tasks. A custom distributed server can be embedded with various software solutions like MES (Manufacturing Execution System), YMS (Yield Management System), EES (Equipment Engineering System), and ATS (Archive & Tracing System). In this we have an integrated solution of software and hardware that can be operated on-site. The distributed server includes a customizable motherboard for big data processing. Some specs are listed below:

- motherboard for customized ODM server for big data processing

- 7 nodes – 5 CPU nodes, 1 Hub node, 1 Power node

- Backplane and Daughter Board for node connection

- 19“ Rackmount, portable case, installed according to factory site conditions

- Server control tools for smart control of distributed servers

B. Smart gateway

A smart gateway is the most important device for building factory automation. A smart gateway connects field devices and sensors to enhance data collection and remote control functions, so smart gateway product specifications need to reflect the needs of the factory site. SyncusTech develops customized motherboards for smart gateways in fields that require simple control functions but still collect large amounts of data and process it on a server.

- Developed Freescale motherboard with the application of ARM Cortex-A9 i.MX6 Dual Core CPU

- Employed and developed CAN, GPIO, multi port RS232C I/F modules

- Chassis design specialized for dust and heat protection functions to enable operation at factory sites

C. EQ CIM controller

It usually doesn’t make sense to implement an ARM CPU using standard software and hardware, so we are developing an EQ CIM controller. The controller will have CPU-based motherboards which are optimizable for the site depending on what functionality is required.

- Developed high-performance low-power x86 board with the application of Intel® Core™ i7 mobile CPU

- Developed embedded onboard Ethernet, GPIO, I2C, USB, Serial I/F

- Chassis design specialized for dust and heat protection functions to enable operation at factory sites

- Developed vPro or iPMi support function for remote control

D. Peripheral Box

The Peripheral Box is a device for physically connecting smart controllers with other hardware of various types that may already be installed in the factory. As the peripheral box needs to be developed for universal use on-site, it is designed to be installed inside a smart controller according to the factory site conditions.

- Developed GPIO Control Box capable of selective application according to service environment

- Developed A/D Converter Box in the form of 4ch, 18bit as required by factory site

- Developed USB to CAN Converter Box capable to supporting CAN Bus communication devices in x86